What is a LaMont Boiler? its construction, working, advantages, uses with PDF

Today at The Mechanical post we”ll see about what is a LaMont Boiler? its construction, working, advantages, limitations and applications.

In the end, you can download the PDF on LaMont boiler by clicking on the button provided.

Introduction to LaMont Boiler.

LaMont Boiler is a type of high-pressure water tube boiler. In 1918 Walter Douglas LaMont, a lieutenant commander and an engineer in the US Navy introduced the forced circulation boiler. The LaMont boiler is named after him.

Before starting, do check out our article on the Thermal power plant – its layout and working for better understanding.

What is a high-pressure boiler?

A boiler that has an operating pressure of above 70 bar, along with a temperature above 250 degrees F is known as a high-pressure boiler.

Working principle of LaMont boiler

The LaMont boiler works on the principle of forced circulation of water in the boiler with the help of a centrifugal pump.

Construction of LaMont boiler

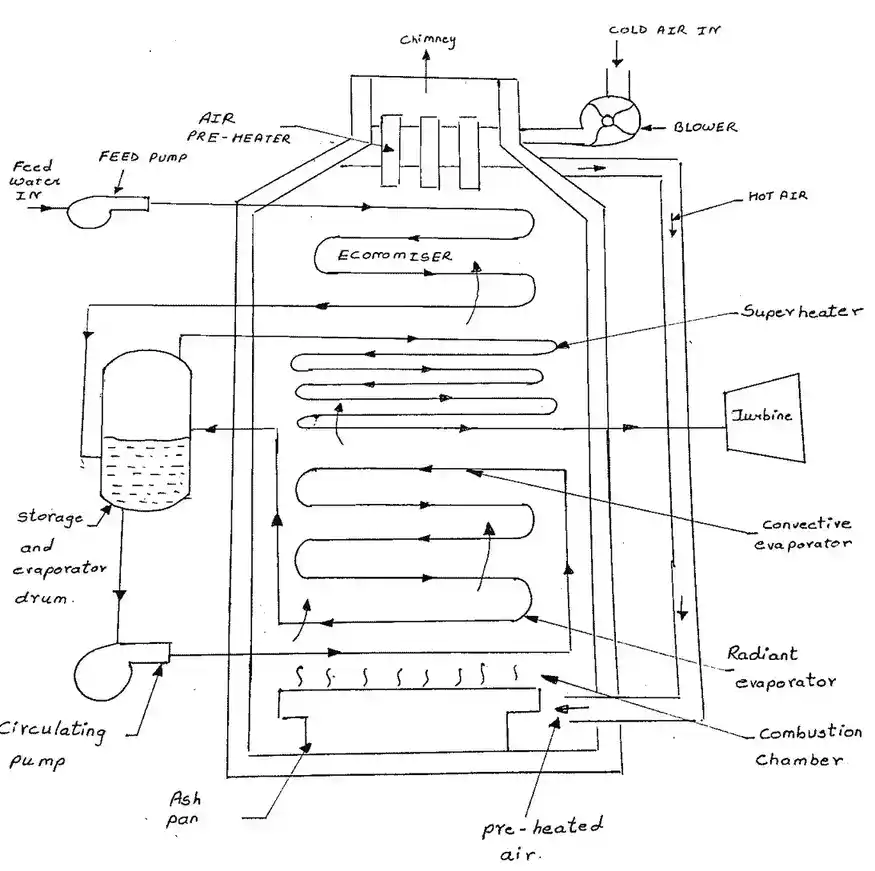

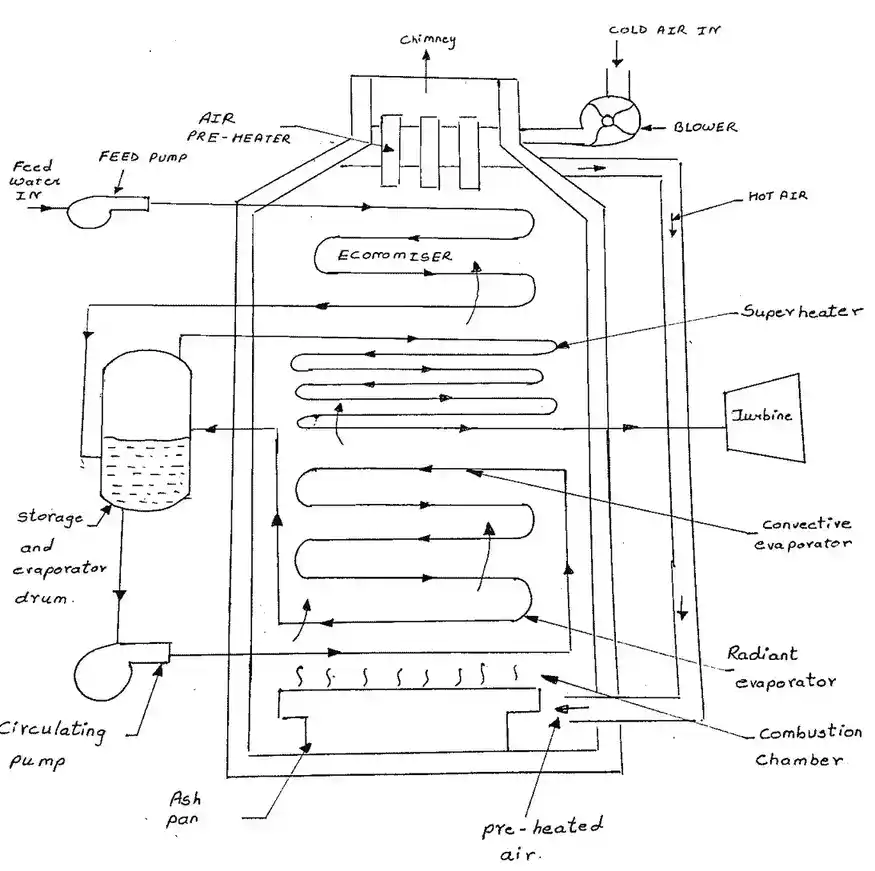

The LaMont boiler consists of the following components: (refer the figure given below)

- Centrifugal Pump

- Economizer

- Combustion chamber

- Radiant Evaporator

- Convective evaporator

- Superheater

- Storage and evaporator drum

- Air preheater

Centrifugal pump

The centrifugal pumps help maintain the flow of water and steam in the boiler. It is the centrifugal pumps that circulate the water and steam at high pressure.

Economizer

The economizer is placed in the path of flue gases. The main function of the economizer is to heat the feed water. It consists of tubes with a feedwater pump attached to it. The feed water is taken up from the reservoir and circulated through the economizer where the feed water is heated before entering the storage and evaporator drum.

Combustion chamber

The combustion chamber is used to produce the heat required to convert water into steam. It is located at the bottom of the boiler. Coal, oil, or natural gas are the types of fuel usually used for combustion. Under the combustion chamber, an ash pan is provided, from where the burnt coal can be collected and disposed off.

Radiant Evaporator

The radiant evaporator is placed as near as possible to the combustion chamber. It consists of small diameter tubes with high-pressure water flowing inside it.

Convective Evaporator

The convective evaporator is placed after the radiant superheater, it is the same as the radiant evaporator except for a small difference. The main difference between the radiant and convective evaporator is that the radiant evaporator gets heated by the radiation of the flames, whereas, the convective evaporator gets heated by convection (i.e. hot gases flowing over the pipes thus heating it.)

Superheater

The superheater is just like an evaporator however instead of water flowing through the tubes, steam is passed through it. The main function of the superheater is to heat the saturated steam to a higher temperature.

Storage and evaporator drum

As the name suggests the water and storage drum is used for storing the feed water, and when it is converted into steam it is also stored here before it is sent to the superheater. The steam is collected in the upper portion of the drum, whereas water is collected in the lower portion of the drum. It is placed outside the boiler as shown in the figure below.

Air pre-heater

The air preheater is placed at the very top of the boiler. Its main function is to heat the air before it is sent to the combustion chamber. The hot gases which leave the boiler help in the heating of the fresh air. This helps reduce thermal stresses in the combustion chamber as well as increase the efficiency of the boiler.

Do you know?

The Air preheater and the economizer mentioned above are boiler accessories. They help increase the efficiency of the boiler.

Coincidentally, We have a detailed article on Boiler mountings and accessories so do check it out!

Working of LaMont boiler

The working of the LaMont boiler is as follows:

- The atmospheric air enters the air preheater at the top with the help of a blower. The air gets warmed up in the air preheater and is sent to the combustion chamber.

- The main reason for preheating the air for combustion is that if normal cool air is used, it would take up heat from the combustion chamber, thus cooling it. So to maintain a constant temperature in the combustion chamber air preheating is done.

- Now, the feedwater is pumped to the economizer for preheating. The economizer warms up or say it provides sensible heat to the feedwater (i.e. there is no phase change, the heat provided only increases the temperature of the feed)

- This heated water is then sent to the Storage and evaporator drum for storing.

- This water is then pumped by the circulating pump to the radiant and convective evaporators, wherein phase change from water to saturated steam takes place.

- This saturated steam is then sent back to the storage and evaporator drum, from where it is passed to the superheater. The superheater provides sensible heat to the saturated steam because of which its temperature increases.

- This superheated high-pressure steam is then sent to the turbine where the rotary mechanical energy of the turbine is converted into electrical energy.

This is how the LaMont boiler works.

You might also like to read:

- Hydroelectric power plant – layout and working with PDF

- What is a Cochran boiler?

- Draft tube and its types with PDF

- Reciprocating pump – construction and working with PDF

- Air compressors – types, working, advantages, and uses with PDF

Advantages of LaMont boiler

The following are the advantages of LaMont boiler;

- The boiler can be easily started.

- High steam generation capacity.

- Simple in design.

- High heat transfer rates can be achieved.

- Since the water in the tubes flows at a high velocity, the problem of scaling is reduced.

Disadvantage of LaMont boiler

The major limiting factor of the LaMont boiler is that the tubes in the boiler tend to form bubbles on the surface, resulting in reduced heat transfer rate and thus affecting the rate of steam generation. This causes a decrease in the efficiency of the boiler.

Applications of LaMont boiler

The applications of LaMont boiler are:

- To produce high-pressure steam for electricity production.

- For industrial heating purposes.

- It also has applications in textile industries, food processing industries, etc.

Some FaQ :

What is meant by saturated steam?

The condition wherein a given amount of water is fully converted into steam is known as saturated steam.

Is Lamont boiler a Fire tube or Water tube boiler?

The LaMont boiler is a water tube boiler.

What is the operating pressure range of LaMont boiler?

The operating pressure range of the Lamont boiler is upwards of 120 bar with a capacity of 50 tonnes per hour.

What is meant by a water tube boiler?

The LaMont boiler is a water tube boiler, which means that in the tubes of the boiler water flows, whereas, the heating gases flow over it.

So that’s an overview of the LaMont boiler. Do comment if you like this post or have any suggestions, we would love to hear from you.

We’ll be back soon with another interesting article till then Keep learning and read The Mechanical post!