What is a boiler? its types, Fire tube, Water tube, uses with PDF

- What is a boiler?

- Working principle of boiler

- Requirements of a good boiler

- Types of boiler

- Fire tube boiler

- Water tube boiler

- Difference between fire tube and water tube boilers

Therefore, for producing steam in large quantity at a desired temperature and pressure a boiler is used. So let’s see what is a boiler.

What is a boiler?

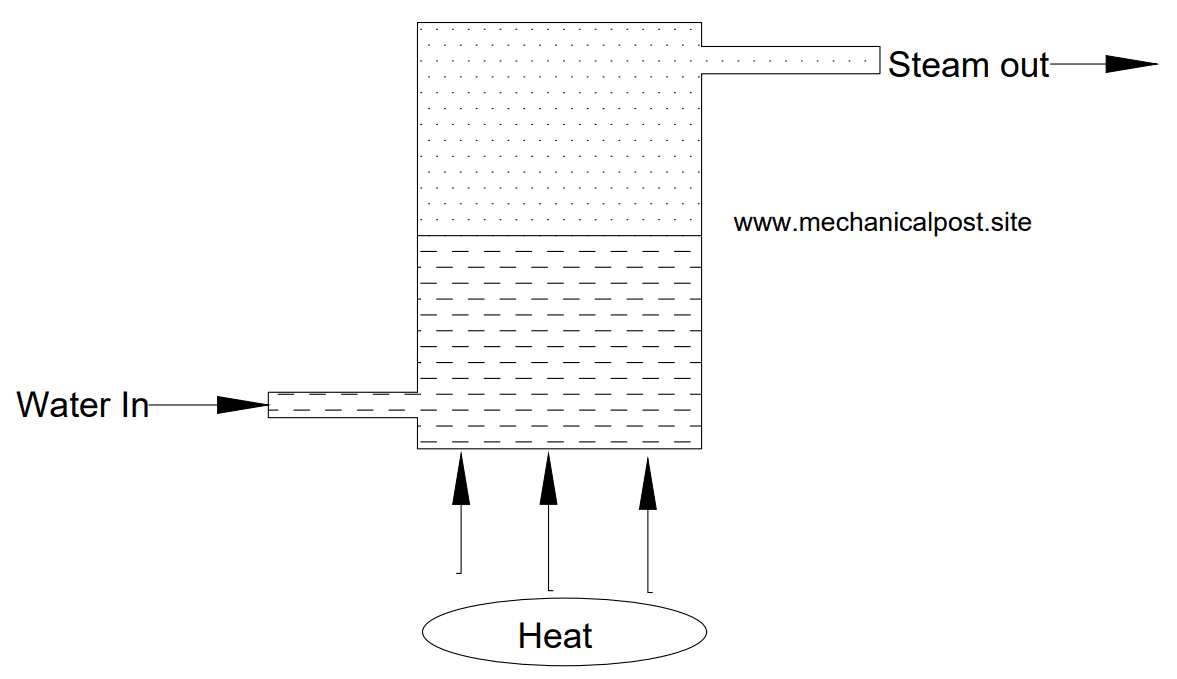

Working principle of boiler

|

| Usage of this image is allowed, however, attribution with a link is required |

Boiler shell

Furnace

Grate

Feedwater

Requirements of a good boiler

- The initial investment, installation and maintenance expenses must be as low as possible.

- The boiler should be capable of generating steam at the desired pressure and quality as quickly as possible with minimum fuel consumption.

- The boiler should occupy the lesser area.

- The boiler should be capable of keeping up with the fluctuating demands without any pressure loss.

- All the parts of the boiler should be easily reachable for cleaning and inspection purposes.

- The boiler should have minimum joints as possible as to avoid any leakage, which may occur due to expansion and contraction of metal because of heating and cooling.

- The boiler should be raised at the site within moderate time and labour.

- There should be no deposition of mud and foreign materials on the inside surface and on the outer surface of heat transferring parts.

- The boiler should be in accordance with the safety regulations laid down by the Indian boiler act. (This is for boiler’s in India, you may check out about boiler rules and regulations in your country)

|

| Photo by CEphoto, Uwe Aranas | A steam locomotive which makes use of a boiler for woking. |

Types of boiler

- Fire tube boiler

- Water tube boiler

- Externally fired – The furnace is placed outside the boiler.

- Internally fired – The furnace is placed within the boiler.

- Mobile boiler – The boiler is portable and can be shifted easily.

- Stationary boiler – The boiler is not portable

- Natural circulation boiler – The circulation of feedwater and steam is natural.

- Forced circulation boiler – Circulation of feedwater is with the help of pumps.

- Horizontal boiler

- Inclined boiler

- Vertical boiler

Fire tube boiler

|

| Drawn using XaraXtreme by Emoscopes, CC BY-SA 2.5, via Wikimedia Commons |

Advantages of a fire tube boiler

- Fire tube boilers are simple in design and rigid in construction.

- Due to simplicity as compared to water tube boilers, its cost is less.

- If the Fire tube boiler is constructed with a vertical drum, the floor area occupied is less.

- In case of failure of feed water to the boiler, no major damage is caused as the boiler already contains a large quantity of water.

Limitations of fire tube boiler

- Fire tube boilers take more time to reach the operating pressure and temperature.

- It has low operating pressure.

- The maximum generating capacity of fire tube boilers is around 9000 kg/hr.

- It has a slow steam generation rate, as a result, it cannot be used in thermal power plants.

- Due to the large size of the shell, the transportation of the boiler is not easy.

Applications of Fire tube boiler

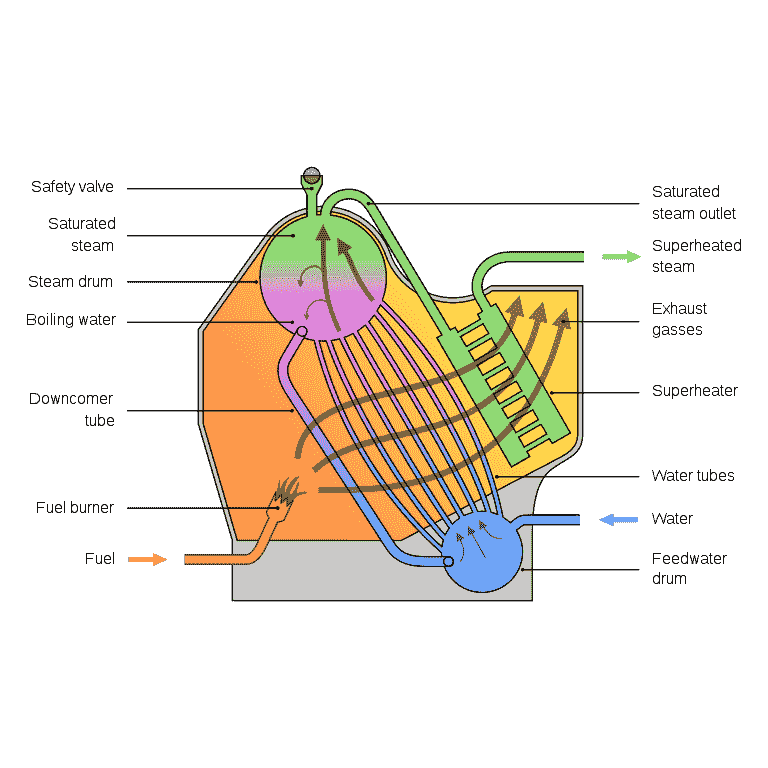

Water tube boiler

|

| Jooja, CC BY-SA 4.0, via Wikimedia Commons |

Advantages of Water tube boiler

- Water tube boilers can quickly reach operating pressure.

- Generation of steam is quick.

- The parts of the boiler can be dismantled easily, thus making it easy to transport.

- All the parts of the boiler can be easily accessed for inspection, maintenance, cleaning and repair purposes.

Limitations of water tube boiler

- Water tube boiler needs careful observation.

- It can be dangerous if impure or hard water is used as it can cause scale formation inside the tubes. This scale formation is can clog the small diameter tubes eventually leading to overheating and finally bursting.

- Maintenance cost is high.

- Continuous feedwater supply is required. In case of failure even for a short period, can cause overheating in the tubes.

Applications of water tube boiler

Difference between water tube boiler and Fire tube boiler

|

Sr no |

Water tube boiler |

Fire tube boiler |

|

1. |

In water tube boiler, water is circulated in tubes and hot gases are passed over it. |

In Fire tube boiler, Hot gas is circulated through the tube and water flows over it. |

|

2. |

It can generate steam at higher pressure (more than 25 bar).

|

It can generate steam at a lower pressure (up to 25 bar). |

|

3. |

Steam production rate is high.

|

Steam production rate is low. |

|

4. |

It can produce steam up to 550˚C.

|

It can produce steam up to 300˚C |

|

5. |

Water tube boilers are generally at the outer part fire type.

|

Fire tube boilers are generally at the outer part water type. |

|

6. |

Water tube boilers are well suited for large power plant.

|

Fire tube boilers are not suitable for a large power plant. |

|

7. |

Due to high operating pressure, there is more chance of explosion.

|

Due to low operating pressure less chance of explosion. |

|

8. |

The diameter of the shell is small in a water tube boiler. |

Larger shell diameter as compared to water tube for the same capacity of steam generation.

|

|

9. |

Various parts are accessible for inspection while the boiler is working.

|

Various parts are not accessible for cleaning and inspection when the boiler is working. |

|

10. |

It requires more attention.

|

It requires less attention. |

|

11. |

It occupies less floor area, as the rate of heat transfer is high. |

It occupies more floor area, as the rate of heat transfer is less as compared to a water tube boiler if shell or drum is in a horizontal position.

|

Some FAQ

What are boilers used for?

What is Fire tube boiler?

What is a Water tube boiler?

That’s an overview of Boilers and its types. If you like this post or have any suggestions do let us know in the comments we would love to hear it from you.

Also do consider subscribing by clicking the subscribe button and never miss a post by us!

We’ll be back soon with another interesting article till then Keep learning and read The Mechanical post!