Reciprocating air compressors – working, types and uses with PDF

Hello there! Today at The Mechanical post we will see What are reciprocating air compressors, their classification, construction, working, advantages, disadvantages, and applications.

Definition of Reciprocating compressor

Reciprocating compressors are a type of positive displacement compressors which by virtue of reciprocating motion compress the air/gas.

What is a positive displacement compressor?

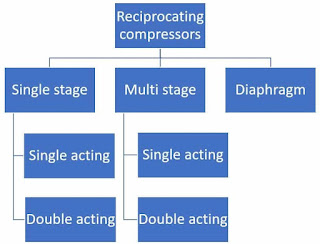

Types of reciprocating compressor

|

The above figure is free to use however attribution to The Mechanical post is needed. |

- Single-stage reciprocating compressor

- Multi-stage reciprocating compressor

- Diaphragm reciprocating compressor

- Single-acting

- Double acting

What is a stage in a compressor?

Single stage single acting reciprocating compressor

|

No machine-readable author provided. Yyy assumed (based on copyright claims)., CC BY-SA 3.0, via Wikimedia Commons |

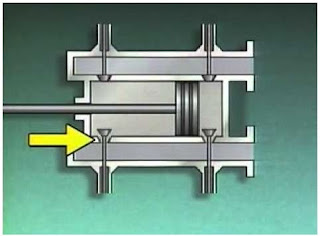

Construction of Single acting reciprocating compressor

- It consists of an air-tight piston and cylinder arrangement.

- The piston is connected to a connecting rod which is connected to a prime mover. The prime mover can be an engine or an electric motor.

- The cylinder is provided with inlet and outlet valves as shown in the figure.

Working of Single acting reciprocating compressor

- The prime mover provides reciprocatory motion to the piston.

- This causes the piston to move to and fro in the cylinder.

- When the piston moves backward it creates a vacuum thus sucking in the air/gas through the inlet valve.

- As the piston moves forward it compresses the air by applying force. And as the piston reaches its furthermost point, the compressed air exits through the outlet valve.

- As the air is compressed its temperature increases considerably.

- Thus in two strokes of the piston, the air is compressed.

- However, the output of compressed air is not continuous as only during 1 stroke compression occurs.

What is meant by single acting and double acting?

Single-stage double-acting reciprocating compressor

Construction of Single stage double acting reciprocating compressor

- It consists of a piston enclosed inside a cylinder.

- The piston is connected to a prime mover for providing reciprocating motion.

- The cylinder has an inlet and outlet valve at one end along with another set of inlet and outlet valves at the other end as shown in the figure below.

Construction of Single stage double acting reciprocating compressor

- As the piston reciprocates from one end to another two actions take place i.e on one as the piston advances compression occurs, whereas simultaneously on the other side of the piston suction occurs. Hence the name double-acting.

- As the suction and compression take place simultaneously the total output is continuous as compared to the intermittent output in single-acting.

You might also like to read :

- Centrifugal pump – its construction and working

- Hydroelectric power plant – layout and working

- What are manometers and what are its types?

- Gas turbine power plant – construction and working

- What is a piston pump?

Multi-stage single acting reciprocating compressor

Construction of Multi-stage single acting reciprocating compressor

- A multi-stage reciprocating compressor consists of two or more stages placed separately.

- An intercooler is placed between the stages.

- The intercooler’s input is connected to the output of the first stage and the output of the intercooler is connected to the input of the next stage.

- Inside the intercooler, cold water is circulated to cool down the compressed air.

- It can be said that the intercooler is a bridge connecting the different stages.

Working of Multi-stage single acting reciprocating compressor

- The air/gas at lower pressure enters the first stage and is compressed to a particular pressure.

- During this, the temperature of the air rises considerably.

- The output of the first stage passes through the intercooler where the air/gas temperature is brought down.

- The high-pressure air/gas enters the next stage and is compressed at an even higher pressure.

- This compressed gas is then exited to its destination via the outlet valve.

Multi-stage double-acting reciprocating compressor

|

Brian S. Elliott, CC BY-SA 4.0, via Wikimedia Commons |

Diaphragm reciprocating compressor

Advantages of reciprocating compressors

- It is used where high compression is required.

- It is inexpensive as compared to other types of compressors.

- It is easy to maintain.

- It has a good working life.

- It is durable.

Disadvantages of reciprocating compressors

- It requires a considerable amount of floor area.

- It produces loud noise during operation.

- It gives intermittent i.e not continuous output (except double-acting compressors).

- Due to reciprocating element frictional resistance is more.

- Since there is more frictional resistance there is considerable wear.

- During compression, the temperature of air/gas increases considerably. Thus an intercooler is required especially in a multi-stage compressor.

Applications of reciprocating compressors

- Reciprocating compressors are used in oil refineries.

- For pumping in gas pipelines.

- It is also used in chemical industries.

- It is also used in many refrigeration and air conditioning systems i.e vapour compression cycle.

That’s an overview of the Reciprocating air compressors. If you like this post or have any suggestions do let us know in the comments we would love to hear from you.

Also do consider subscribing by clicking the subscribe button and never miss a post by us!

We’ll be back soon with another interesting article till then Keep learning and read The Mechanical post!

I am impressed by the details that you have shared in this post and It reveals how nicely you understand this subject.

very good content bro. keep the good work and also thnx for the help