Foot step bearing – its construction, assembly and limitations

Welcome back to The Mechanical post! Today in this article we will see about What is Footstep bearing? its construction, assembly, and limitations.

What is a Foot step bearing ?

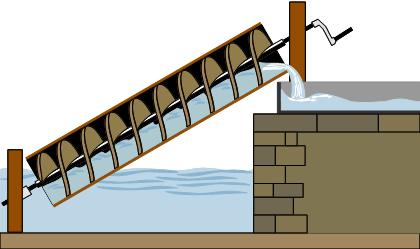

A footstep bearing is a cylindrical rigid block with a solid foundation. It has a cavity inside it within which the shaft is placed. The footstep bearing supports a vertical shaft.

Many a time vertical shafts overhang, thus the footstep bearing is used as end support.

Long shafts in machines, when in use tend to bend due to their own weight and thus cause vibration, noise, and inefficient power delivery.

A Footstep bearing enables free rotation of the shaft inside it, also while supporting it with minimum resistance.

Construction of Foot step bearing

The footstep bearing is made up of the following components:

- The body

- Disc

- Pin

- Bush

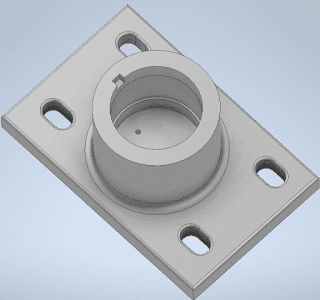

The body

The base also known as the body is made up of Grey cast iron, spheroidal cast iron, or cast steel and is bolted to a foundation or a rigid structure.

The body has a cylindrical extrusion inside which a small hole for the pin to fit is provided as shown in the figure below. There is a small cut-out at the top part of the cylinder for locking the snug of the bush.

Disc

The disc is a circular part with its top surface being concave. The disc is placed at the bottom of the cylinder of the body, such that the hole of the disc and the body align perfectly.

The main function of the disc is to support the face of the shaft and prevent the wear of the body due to the rotating of the shaft.

The disc is made up of softer material like gunmetal. The disc gets worn out due to the rubbing action and is easily replaceable.

Pin

The pin is made up of Fe 410W. The function of the pin is to secure the disc to the body and prevent the disc from rotating due to the rotation of the shaft.

Half part of the pin is in the body whereas the other half is inside the disc.

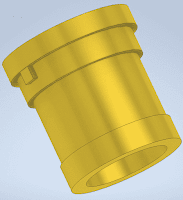

Bush

The bush is a hollow cylindrical part inside which the shaft is placed. The bush is placed inside the cylindrical part of the body.

The bush is made up of gunmetal or other soft material and serves the same purpose as the disc. The main function of the bush is to protect the body from wear caused due to the rotation of the shaft inside it.

The bush has an extruded part at the side called the snug. The sung fits in the cut-out of the body. This prevents the bush from rotating when the shaft rotates inside it.

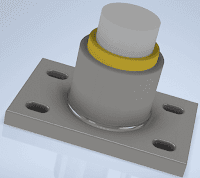

Assembly of the Foot step bearing

- The assembly of the foot step bearing starts with the body. The body is placed and fixed to a strong foundation with the help of the slots provided on the base of the body.

- The pin is then taken and placed into the hole provided into the body.

- The disc is then taken and then placed over the such that the top part of the pin is in the disc.

- Now, the bush is taken and fitted inside the cylindrical body such that the snug fits in its place.

- The assembly is ready, then the shaft is placed inside the bearing.

- The same process is repeated vice versa to dismantle the Foot step bearing.

Limitations of foot step bearing

- Unlike the pedestal bearing or the plummer block, the foot step bearing can be placed at the bottom of the shaft only.

- The foot step bearing cannot be efficiently lubricated.

- Also the bush and disc have to be replaced from time to time due to wear.

That’s an overview of the Footstep bearing. If you like this post or have any suggestions do let us know in the comments we would love to hear from you.

Image credits :

All the above pictures and videos are made by The Mechanical post and it is prohibited to use any of them in any form. If you want to use the pictures, you can contact us here

Also do consider joining our Telegram channel @TheMechanicalpost to never miss an update by us!

We’ll be back soon with another interesting article till then Keep learning!