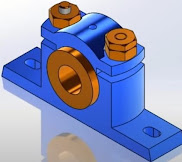

Pillow block bearing (pedestal bearing) – construction and uses.

Hello reader ! Today at The Mechanical post we’ll take a look at plummer block also known pedestal bearing, its construction, assembly and applications.

Introduction to pillow block bearing or pedestal bearing

Plummer block or pillow block is a type of bearing which is used for the purpose of supporting shafts.

Long shafts in machines, when in use tend to bend due to their own weight and thus cause vibration, noise and inefficient power delivery.

A pillow block bearing enables free rotation of the shaft inside it, also while supporting it with minimum resistance.

What is pillow block bearing ?

The pillow block bearing is a type of fixed bearing with strong foundation and is used to support shafts. It is usually used to provide end support to the shaft. This bearing is strong and robust, and with minor changes it can be used almost anywhere.

Construction of Pillow block bearing or pedestal bearing

The pillow block bearing or pedestal bearing consists of the following components:

- The body or base

- Bush or brasses

- Cap

- Bolt

- Nut and lock nut.

The body or base

The base also known as body is made up of Grey cast iron, spheroidal cast iron or Cast steel and is bolted to a foundation or a rigid structure. As shown in the figure the block has a semicircular cut out to house the bush.

It also has a small diameter hole in the semicircular cut out, so that the projection of the bush locks itself into it. This prevents the movement of the bush when the shaft rotates inside it.

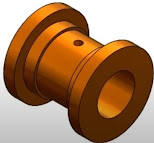

Bush or brasses

The bush is a hollow component and is made up of material softer than the shaft. The shaft rotates inside the bush. Thus the bush must have good bearing properties.

On the top side the bush has a small diameter hole to allow lubricating oil to reach the shaft. At the bottom the bush has a small projection which fits in the hole provided in the block.

It is made up of cast bronze or oil impregnated sintered bronze which has very good mechanical properties suitable for bearings.

For high load environment instead of a bush, ball bearings or spherical roller bearings or self aligning ball bearing is used.

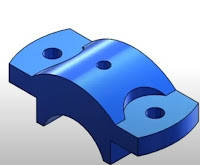

Cap

It is the top part which is placed above the bush and the body as shown in the figure. It has 2 through holes on either end for bolts to pass through. The cap secures the bush and prevents its movement.

The cap has a small hole at the center for lubricating oil to pass via the hole in the bush and reach the shaft. This helps in reducing friction between the shaft and the bush. Thus resulting in reduced wear and tear.

Bolt

Two square headed bolts are used to clamp and hold together the above assembly. These bolts are fitted upside down such that the square head is at the bottom and the threads are at the top passing through the cap.

Nut and lock nut

The nut is used to secure the whole assembly while another nut called the lock nut is used to secure the nut from loosening due to vibrations.

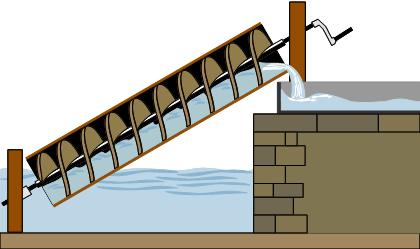

Assembly of pedestal bearing or pillow block bearing

To place the shaft inside the bearing the lock nut and nut are removed. The cap is then taken off. Now the bush is removed and then slid over the shaft. The cap is placed over and then tightened by the nut and lock nut.

|

| Assembly of pedestal bearing |

The same process is repeated vice versa to remove the shaft from the pillow block bearing or pedestal bearing.

Applications of Pillow block bearing or pedestal bearing

- It is used to support rollers in rolling process.

- Conveyor belt shafts.

- It can be used for light as well as high load conditions with some minor changes

- Plummer blocks can be used in corrosive environments with suitable changes.

- To support long shafts.

- It is also used in agricultural machineries.

- As an end support.

- Large fans.

- Industrial grinders.

- Revolving drums etc.

That’s all about pedestal bearing. If you like this post or have any suggestions do let us know in the comments we would love to hear it from you.

From the editor’s desk

If you are interested in reading such mechanical content ( besides your favourite The Mechanical post ) you might want to check out Top 30 Mechanical Engineering Blogs on the internet.

We’ll be back soon with another interesting article till then Keep learning and read The Mechanical post!

Awesome post, I read an interesting topic here, and I like your style. Thanks a million, and please continue with effective work. Thank you for sharing this blog here.