What is Industrial Automation and its Types? [with PDF]

You might have heard the term “automation” numerous times and why not? every process is now being automated around us. Automation is becoming the ‘new normal ‘ for industries worldwide.

Many companies are opting for automation and smart manufacturing solutions to become “smart factories” of the future. Well there are different types of automation but today we’ll see in particular about Industrial automation and its types.

What is Industrial Automation?

Industrial Automation is the technology that uses mechanical, electronic and computer systems to help manufacture and control things in production.

The term “Industrial Automation” is a process in which various tasks in the manufacturing process are performed automatically. The operator is required only for supervision, this enables him to control a number of machines at a time. In today’s world for a company to survive in the cut-throat competition, it must opt for automation.

Need of automation / Advantages of automation.

- Increased labour productivity.

- Reduced labour cost.

- Mitigate the effects of labour shortages.

- Reduced or eliminate routine manual and clerical tasks.

- Improved worker safety.

- Improved product quality.

- Reduced manufacturing lead time.

- Reduced unit cost.

Types of Industrial Automation

Automation can be classified into 3 major categories:

- Fixed automation

- Programmable automation

- Flexible automation

1. Fixed automation :

Fixed automation refers to the use of special-purpose machines to perform a specific task only. These types of automatic machines are made to perform single or at the most two tasks. Fixed automation is capable of manufacturing a particular product style, so any changes in the product design or process means changing the automation system which in turn is quite difficult.

These machines that are used to automate the task are custom-built according to the manufacturing process. As Fixed automation is employed for doing a particular process it becomes difficult for Fixed automation to adapt to new changes in the process. Fixed automation is initially expensive, however, in the long run with high production rates, it becomes economical. Therefore, fixed automation is best suited for mass production.

Fixed automation is also referred to as “Hard Automation”

Examples of Fixed automation:

Examples of fixed automation include automated assembly lines in automobile manufacturing industries, material handling conveyor systems, machining transfer lines, chemical manufacturing systems etc.

Advantages of Fixed Automation are:

- Fixed automation has high production rates.

- Manufacturing cost per unit is lower.

- Uniform quality output.

Limitations of Fixed automation are:

- High Initial investment is required.

- Difficult to adapt to changes.

2. Programmable automation :

Programabble automation refers to the production equipment designed with the capability to change the sequence of operations to accommodate different product configurations. The operation sequence is controlled by a program, which is a set of instructions coded so that the system can read and interpret them. New programs can be introduced into the equipment to produce new products.

Unlike Fixed production which is suitable for mass production, Programable automation is suitable for batch production. In programmable automation, for each new style of product the machinery must be reprogrammed. As the systems are being reprogrammed there is a span of non productive time.

Examples of Programmable automation:

Examples of programmable automation include NC controlled machine tools, industrial robots, CNC machines Programmable logic controllers (PLC) etc.

Advantages of Programmable Automation are:

- Programmable automation is best suited for batch production.

- There is flexibilty to accomodate product change.

Limitations of Programmable automation are:

- Initial cost is high.

- Lower production level as compared to fixed automation.

- Reprogramming is time consuming.

3. Flexible automation :

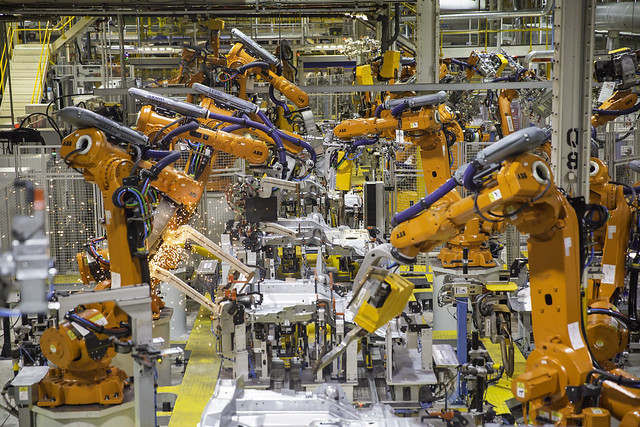

Flexible automation is an extended part of programmable automation. A flexible automated system is one that is capable of producing a variety of products (or parts) with virtually no time lost when changes are made from one product to the next.

There is no production time lost while reprogramming the system and altering the physical setup (tooling, fixtures, and machine setting). Consequently, the system can produce various combinations and schedules of products instead of requiring that they be made in separate batches.

Flexible automation is also referred to as “Soft Automation”

Example of Flexible automation:

Examples of flexible automation include robotic arms that can be reprogrammed to do a variety of tasks like drilling, welding, spray painting etc.

Advantages of Flexible Automation are:

- No time is lost while changes are made.

- Easier to adapt to changes in product.

- It is faster than programmable automation as no time is past in making the changes.

Limitations of Flexible automation are:

- Higher cost of equipment/machinery.

- Manufacturing cost per unit is higher.

All of the above automation can be quite expensive and for small to medium scale businesses it might be a problem. Therefore, for this purpose Low Cost Automation can be implemented.

What is Low cost automation?

- Low cost automation (LCA) is to implement an automation solution at the lowest cost. LCA is defined as “a system where man and machine collaborate and work together, to achieve a goal with less investment”.

- An automation, which is easy to implement with high flexibility and reliability, which occupies less space, that needs zero or minimum maintenance, with minimum investment and running cost, is termed as LCA.

- LCA is one solution especially medium and small scale industries who find it difficult to implement automation.

- LCA involves the introduction of standard equipment, mechanism and devices to convert manual operation to automatic ones by making use of parts or sub-assemblies of old not utilized machines, mechanisms, system which are available free or at very lower cost.

A very delightful article that you have shared here. Your blog is a valuable and engaging article for us, and also I will share it with my companions who need this info. Thankful to you for sharing an article like this.